Understanding Precision Manufacturing from the Leader in Optical Lens Production

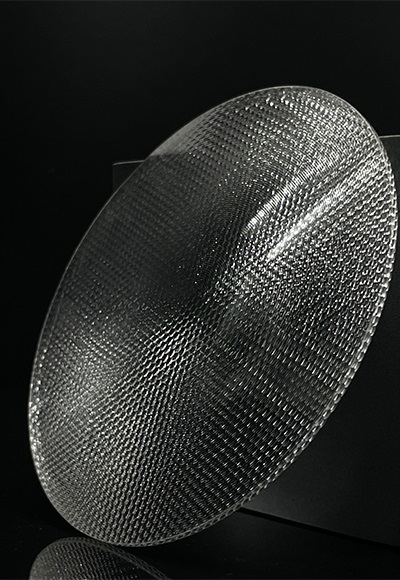

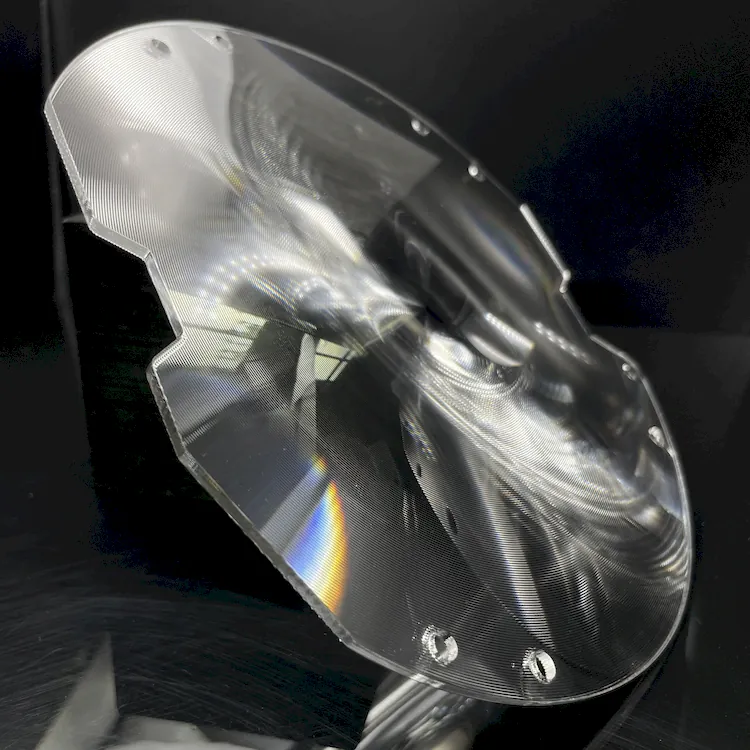

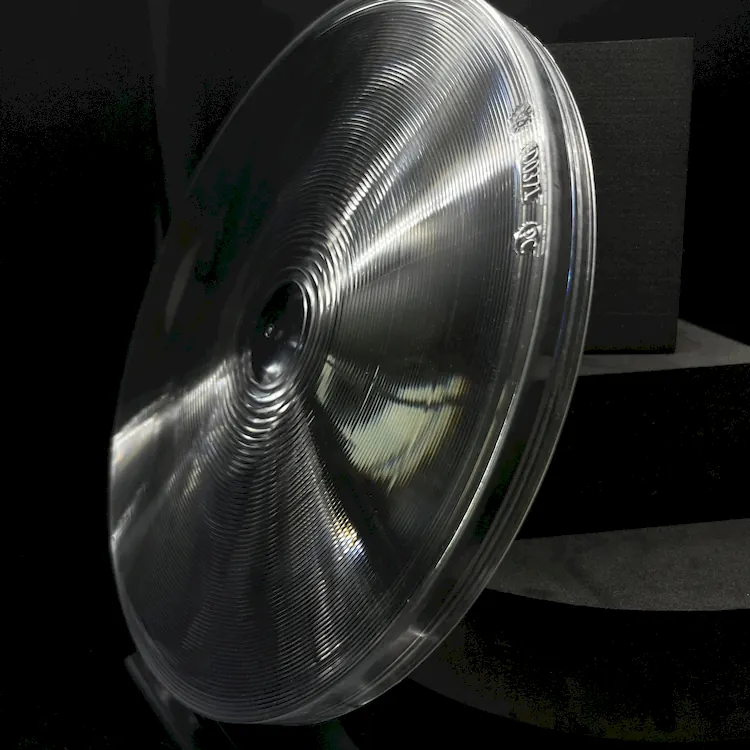

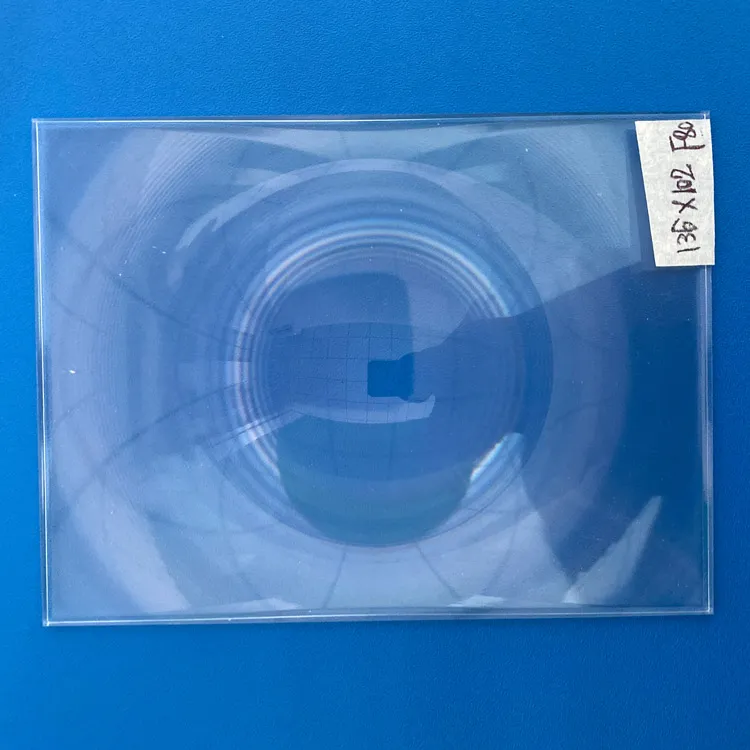

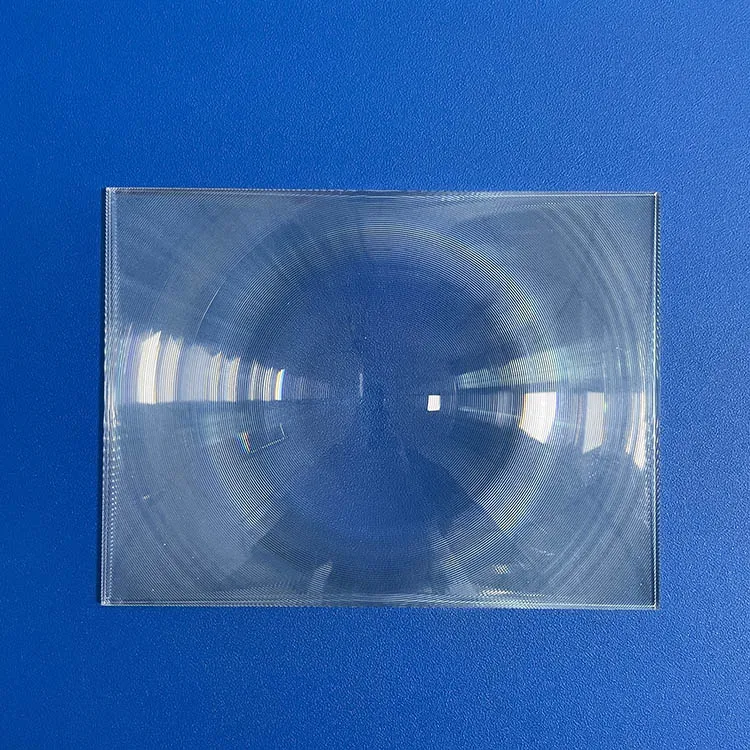

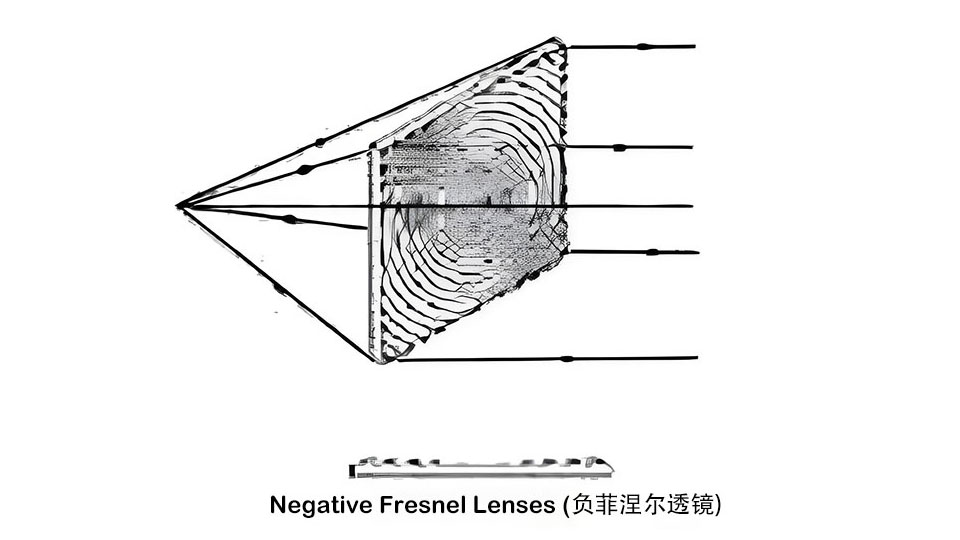

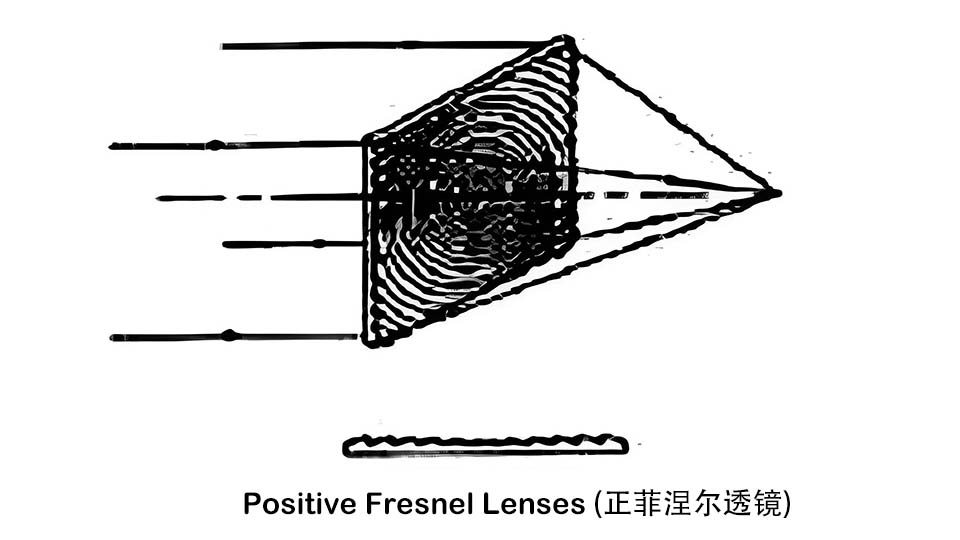

In the field of precision optics, the manufacturing process of a Fresnel lensplays a decisive role in its optical performance.

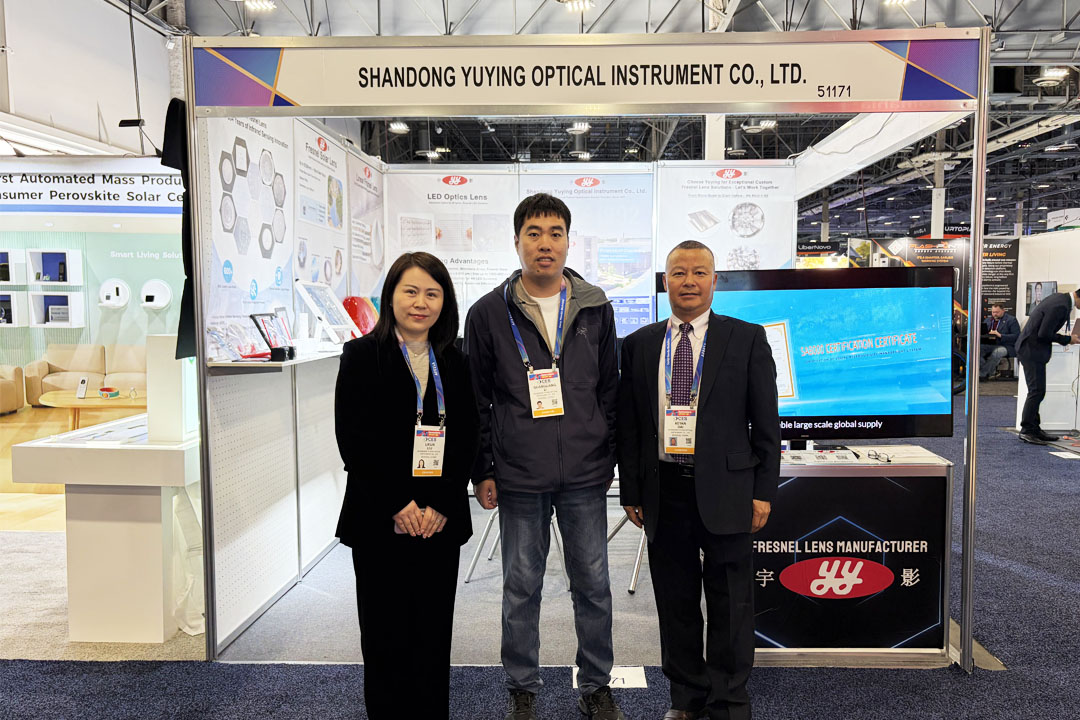

At Shandong Yuying Optical Instrument Co., Ltd., we have over 30 years of experience in Fresnel lens design, tooling, and mass production. Our engineering team has mastered both mold-pressing (模压) and injection molding (注塑) technologies, enabling us to provide the most suitable solutions for different application requirements — from infrared sensing and imaging systems to solar concentration and optical instruments.

1. Core Difference: Lens Groove Formation

The key distinction lies in how the Fresnel grooves are formed.

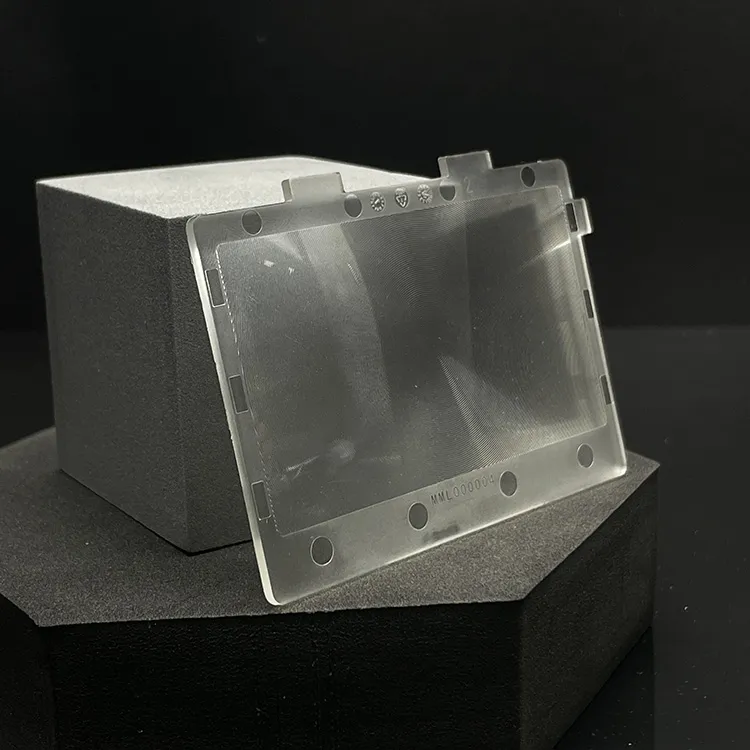

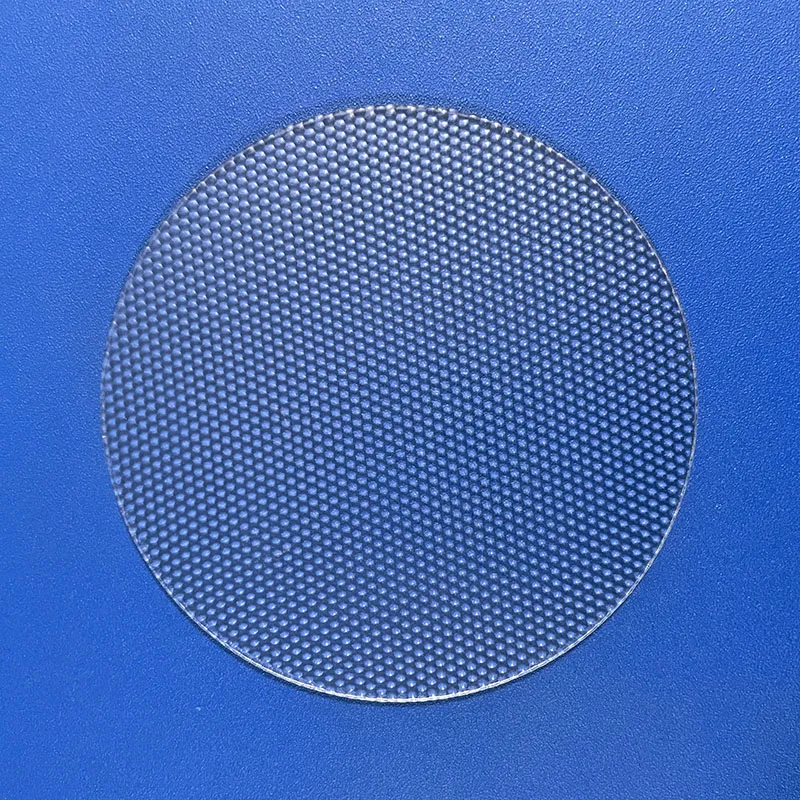

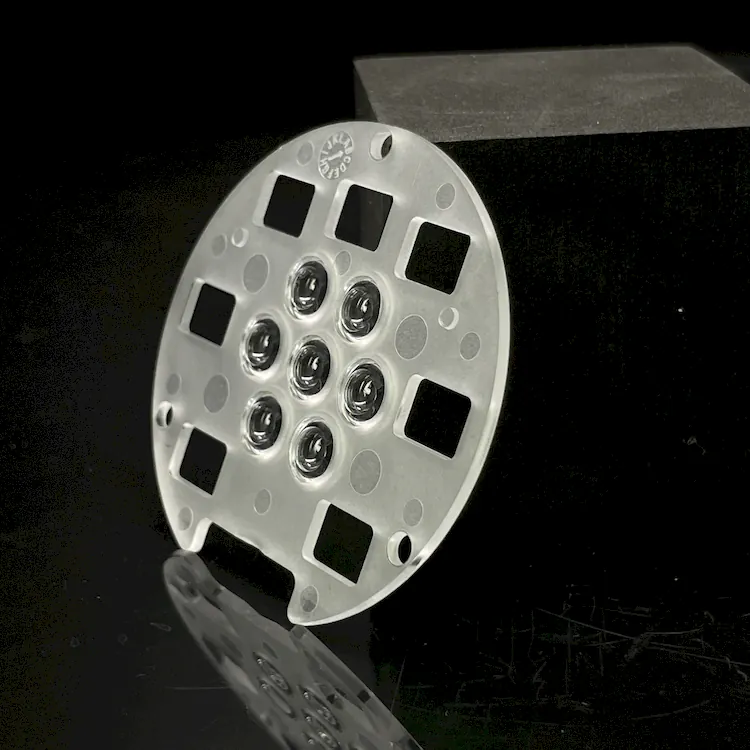

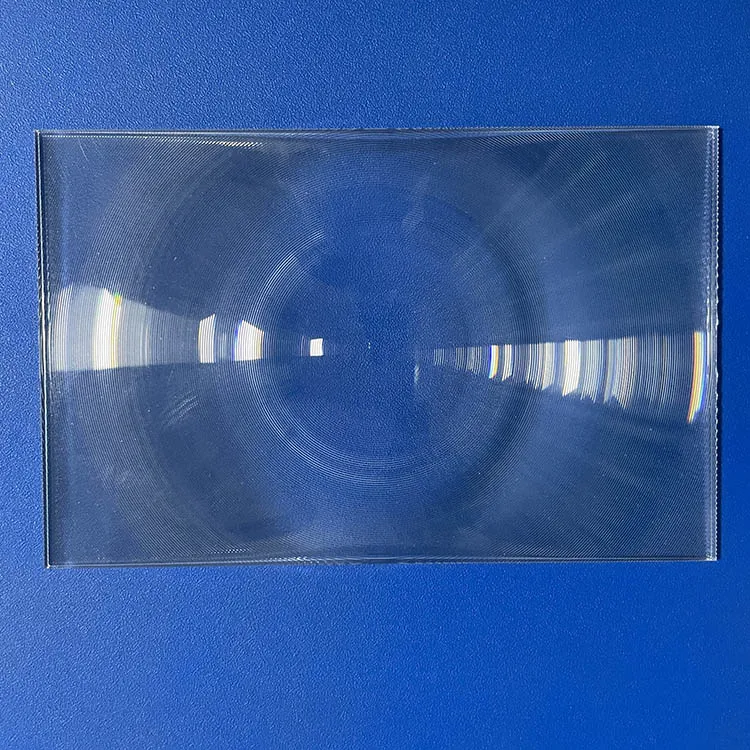

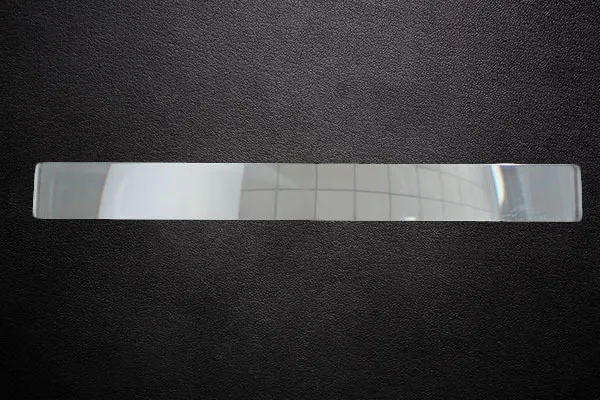

- Injection-Molded Fresnel Lenses

Using high-precision injection molding, molten polymers such as HDPE or PMMA are injected into molds.

The grooves are rounded and smooth, ideal for mass production, PIR sensors, and cost-sensitive applications.

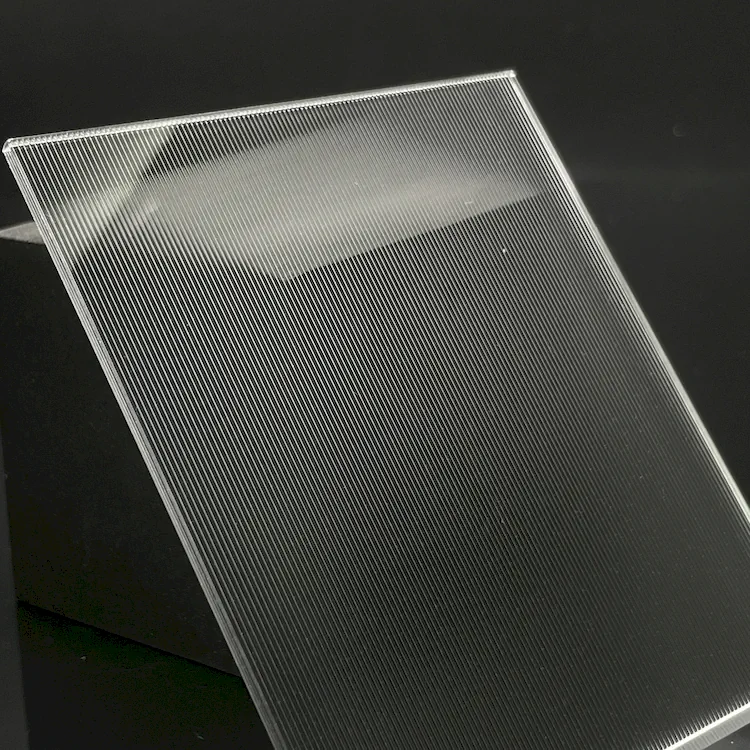

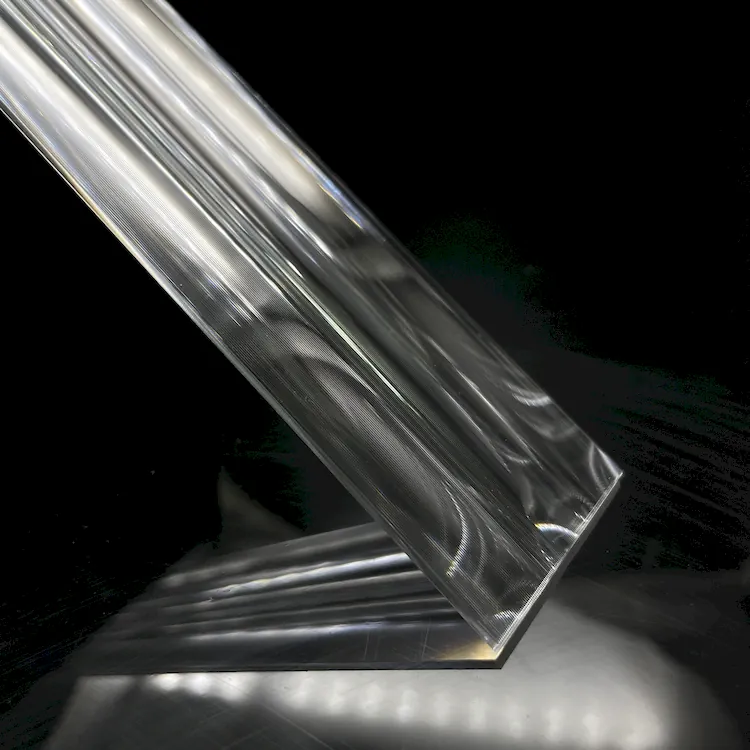

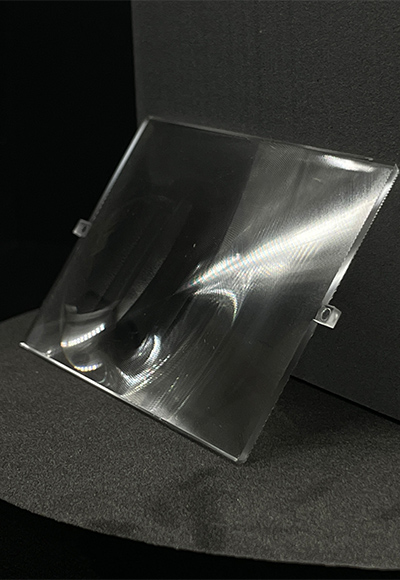

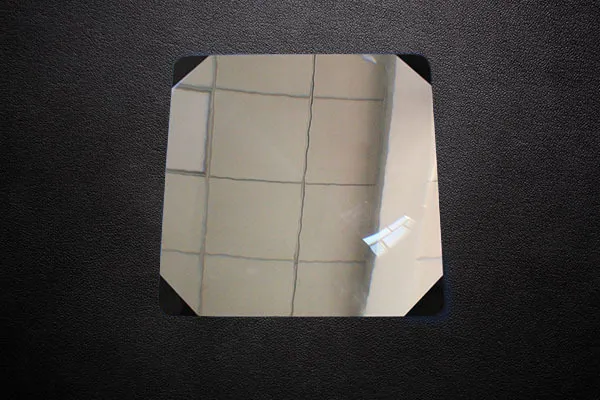

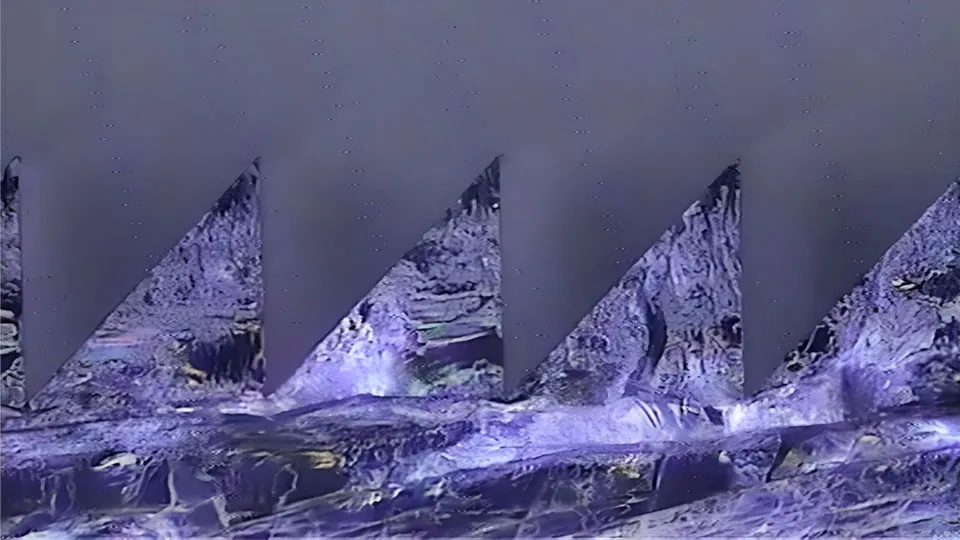

- Mold-Pressed Fresnel Lenses

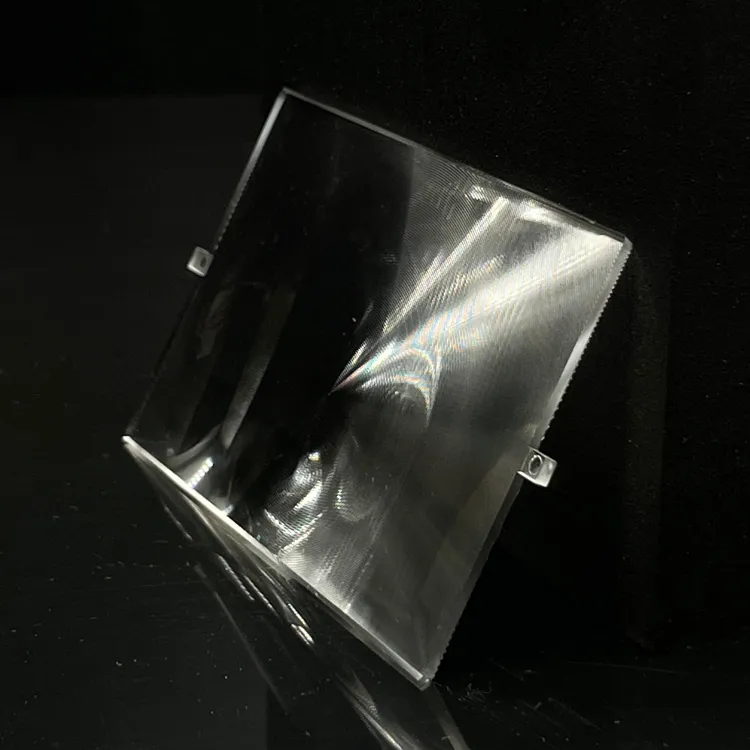

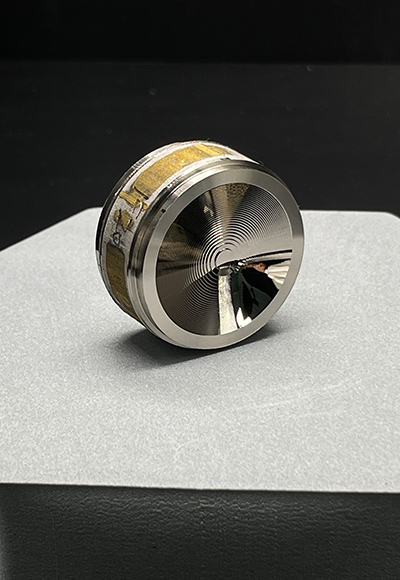

This process applies high temperature and pressure to replicate every microstructure of the mold.

The grooves are sharp, clear, and highly accurate, providing superior clarity, light transmission, and resolution — essential for laser systems, imaging, and scientific instruments.

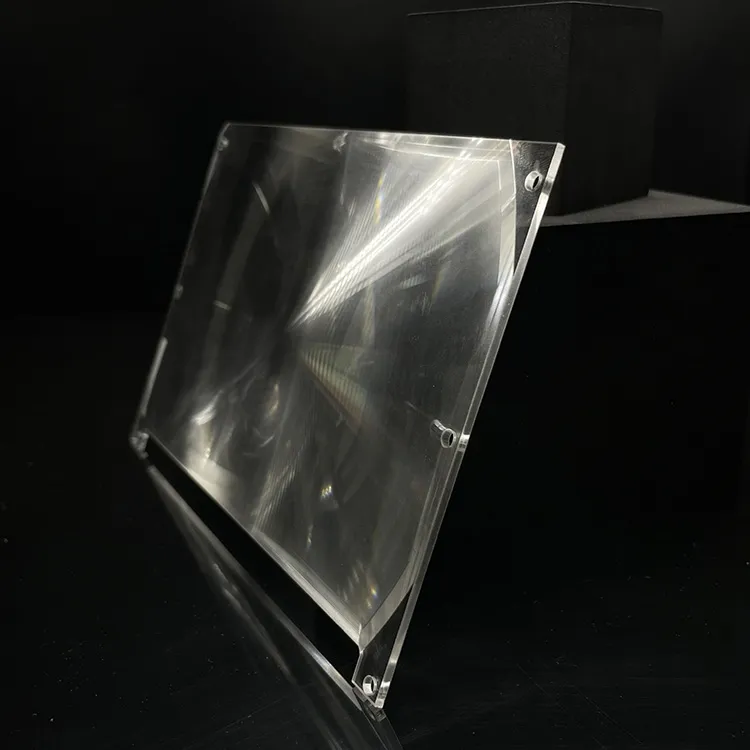

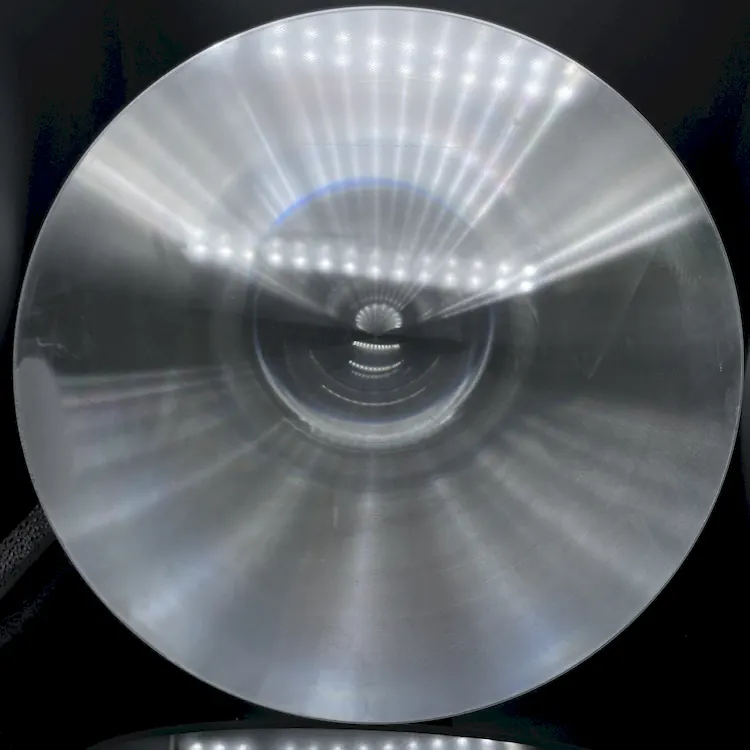

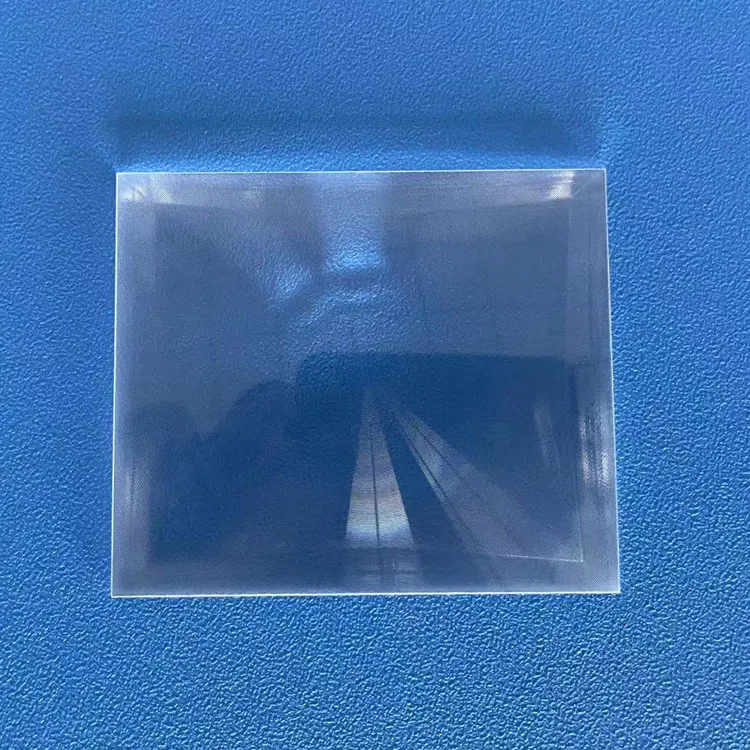

2. Visual and Tactile Differences

When examined closely, you can visibly identify the precision gap:

- Mold-pressed lenses exhibit sharper groove tips, with a crisp tactile edge.

- Injection-molded lenses have smoother transitions between rings, resulting in a softer feel and lower edge definition.

This micro-level difference directly impacts how the lens refracts light — influencing focus accuracy, image contrast, and overall transmission efficiency.

3. Performance Comparison

| Parameter | Mold-Pressed | Injection-Molded |

| Groove Sharpness | Very sharp | Rounded |

| Clarity & Resolution | Higher | Moderate |

| Production Speed | Medium | Fast |

| Cost | Higher (due to precision) | Lower |

| Ideal Applications | Imaging, laser optics, R&D | PIR sensors, lighting, automation |

Mold-pressed lenses provide better optical definition, while injection molding ensures speed and scalability.

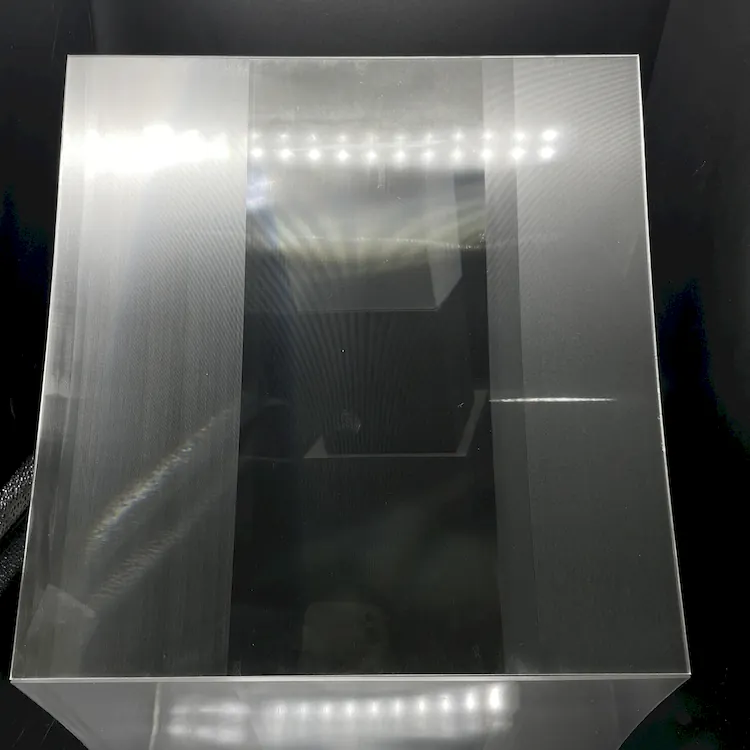

4. Yuying Optical's Technological Strength

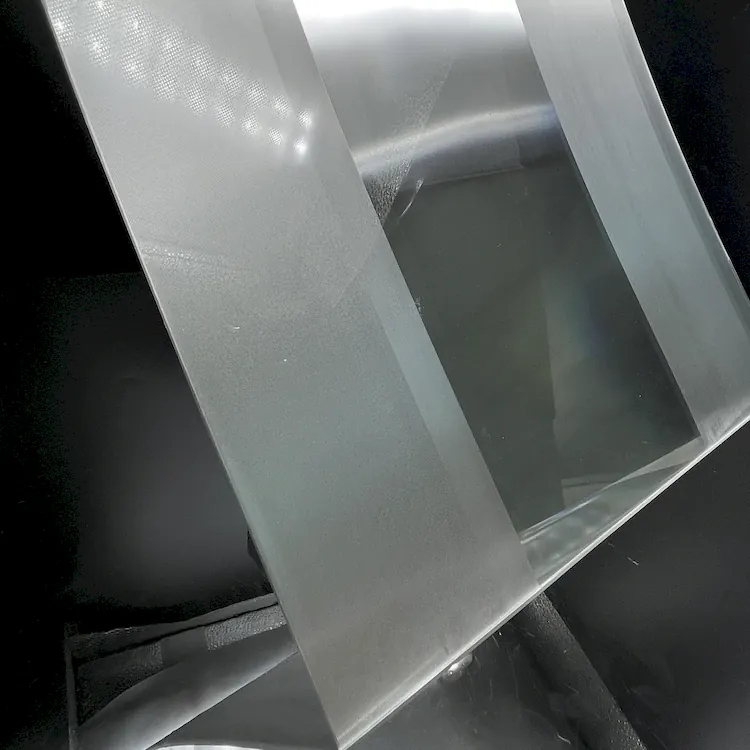

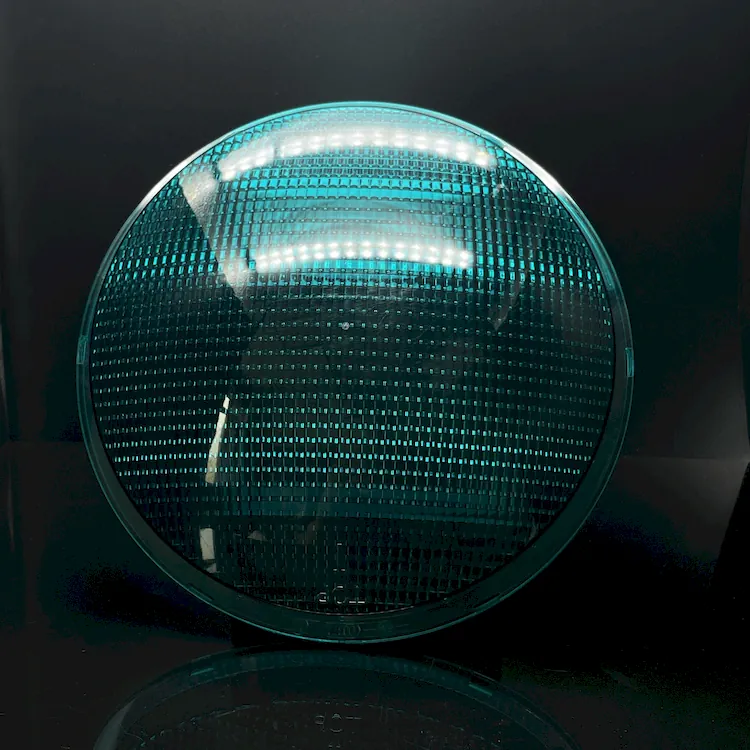

At Yuying Optical, all Fresnel lenses are designed and produced in-house.

We integrate optical design, mold making, and precision molding — ensuring total quality control from concept to shipment.

Our competitive advantages:

- 30+ years of professional experience in Fresnel optics

- In-house mold design and polishing workshop

- Annual production capacity near 100 million units

- Partnered with Midea, Siemens, 3M, and global OEMs

5. Leading Innovation in China's Fresnel Lens Industry

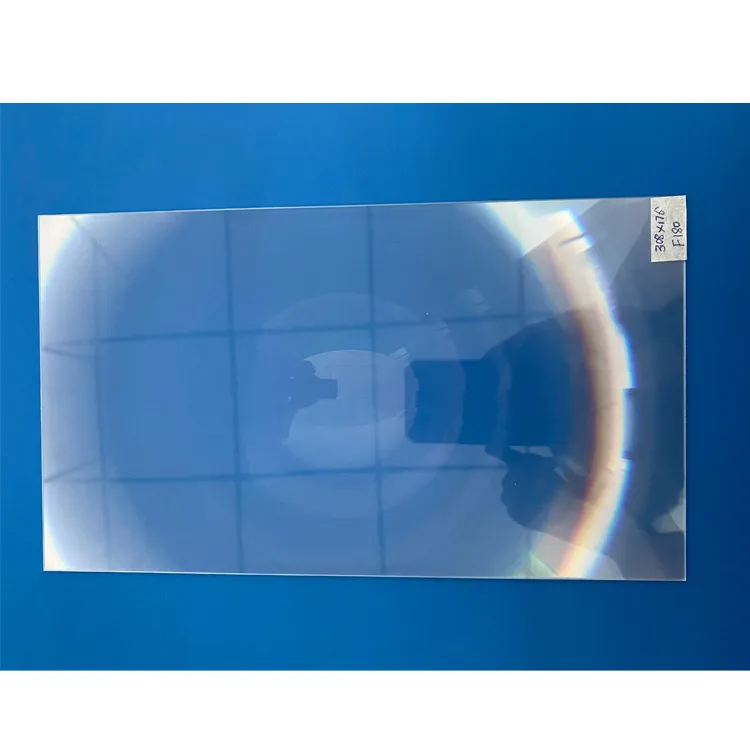

As a leading Chinese manufacturer, Yuying Optical continues to innovate in high-precision optical processing.

We provide custom solutions for various focal lengths, diameters, and materials, supporting customers in automation, smart sensing, and visual systems worldwide.

Yuying Optical – Where Precision Meets Innovation.

Learn more: www.yuyingfresnel.com

[Email] sakura@yuyingfresnel.com | sakura@yuying-sd.com

[Phone | Whatsapp | Wechat ] +86 13826507576